Pulp and Paper Projects

CR Industrial Machine

Machine Works LTD

1311 Spruce St., Campbell River, BC, V9W 3L6

Ph: (250) 286-1175 Fax: (250) 286-1134

Manufacture

Modification Recovery

Paper Machine Transfer

Arms (Set)

The bores were

digitally located off of the large radius.

We overbored to trueup and cleanup, and then oversized bronze bushings

were manufactured. The mating Pedestals were recovered by spray welding and

then re-machined to their original size to match the new bushing bores.

Turbine Pedestal Base

(Set)

Base flange

dialed up true to axis of pedestal bore and warpage of base trued up. Heavy Duty steel base plates manufactured

for grouting into mill

Base flange

dialed up true to axis of pedestal bore and warpage of base trued up. Heavy Duty steel base plates manufactured

for grouting into mill

Sunds Gearbox Housing

Recovery of

the worn bearing bores with replaceable steel sleeves, which are locked into

position and have an oil drain access slot.

The bores are setup true to the boxs mounting flanges! We believe steel sleeves of ample thickness and installation tightness are

superior to a sprayed and re-machined recovery. We have completed this project both ways on request of our

customer.

Recovery of

the worn bearing bores with replaceable steel sleeves, which are locked into

position and have an oil drain access slot.

The bores are setup true to the boxs mounting flanges! We believe steel sleeves of ample thickness and installation tightness are

superior to a sprayed and re-machined recovery. We have completed this project both ways on request of our

customer.

Sunds Pump Housing

Sleeve

recovery of the front and rear bores.

Housing bores are setup true to the mounting feet and flange. It is much easier and safer to setup a

workpiece like this in a boring mill rather than a lathe. Also both bores are machined in one setup

and are perfectly true!

Sleeve

recovery of the front and rear bores.

Housing bores are setup true to the mounting feet and flange. It is much easier and safer to setup a

workpiece like this in a boring mill rather than a lathe. Also both bores are machined in one setup

and are perfectly true!

Alstrom Sulzer/Bingham Worthington Byron Jackson Wemco etc.

Reducer Housing

Bearing bore

recovery dialed up true to main flange area, rear bores and mounting feet

Bearing bore

recovery dialed up true to main flange area, rear bores and mounting feet

Housing Line Bore - Sleeve Recovery

Both bores re-machined in one setup which results in a perfect

alignment!

Valve Body

-offsetting errors in the bolt pattern holes because the mating flange

holes in the mill were hand layed out.

We electronically layout all large bolt patterns of this nature on our

Boring Mill using the onboard computerized Digital Location Readout. We

mechanically index smaller bolt circles on a dedicated post drill fitted with a

rotary table! These procedures save time and money when faced with future

failures and ease of mating OEM replacement components.

Modifying a sealing flange on a SS

housing

Turbine Body recovery,

Valve Body Inspection and reface

Felt Roll bearing pedestals Custom Manufactured

Kinney Strainer - Recovery of the perished lands

Last go for this one due to pitting!, but a few more miles was welcomed.

Reface of the flange areas minimum cleanup

Bronze lands and seat

manufactured, installed and taper machined to suit cone

Thick Two Part Epoxy prime coat to the interior after

sandblasting.

Sunds TMP Refiner Bedding Housings

We internally

mill pockets within the bore to accept special bronze wear strips. This recovery provides extra wear area,

greatly extending time between re-builds.

A pocket for a steel recovery strip of the top keyslot is normally milled in and installed at the second

recovery. We manufacture the Bronze

Wear Strips and Keyslot Insert in house.

We internally

mill pockets within the bore to accept special bronze wear strips. This recovery provides extra wear area,

greatly extending time between re-builds.

A pocket for a steel recovery strip of the top keyslot is normally milled in and installed at the second

recovery. We manufacture the Bronze

Wear Strips and Keyslot Insert in house.

The 22 mating

Bearing Capsule is spray welded with a specially selected powder and

then precision ground to size. The Ground

Finish proves to be far superior to a turned finish in this case providing

exceptional hours between recoveries.

The 22 mating

Bearing Capsule is spray welded with a specially selected powder and

then precision ground to size. The Ground

Finish proves to be far superior to a turned finish in this case providing

exceptional hours between recoveries.

The long and skinny

The long and skinny

the recovery of the bolt patterns

and surface areas of this 14 SS workpiece was very economical.

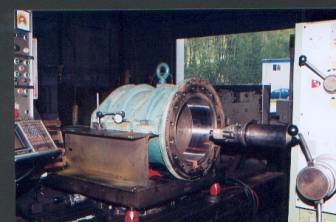

Compressor Barrel - Recovery

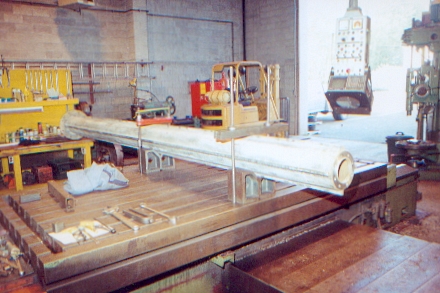

Pulp Auger CR Industrial Machine has the

capacity to get the job done.

CR Industrial Machine has the

capacity to get the job done.

Bud

Couplings

Internal Slotting Precision machining of Bud Couplings for a Paper

Machine drive.

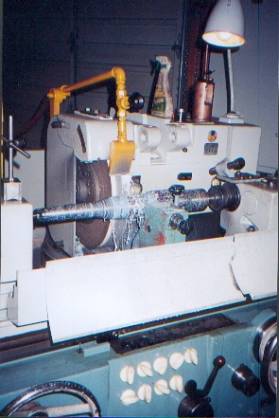

Precision Grinding of a Selectifier Shaft

Precision Grinding of a Selectifier Shaft

There

is no better mating surface for a bushing, bearing or seal than a precision

ground finish Customers inform us that

the hours between recoveries have significantly increased due to our grinding

of seal and bearing surfaces!

CR Industrial Machine

Machine Works LTD

1311 Spruce St., Campbell River, BC, V9W 3L6

Ph: (250) 286-1175 Fax: (250) 286-1134

Manufacture

Modification Recovery